Speed & Efficiency

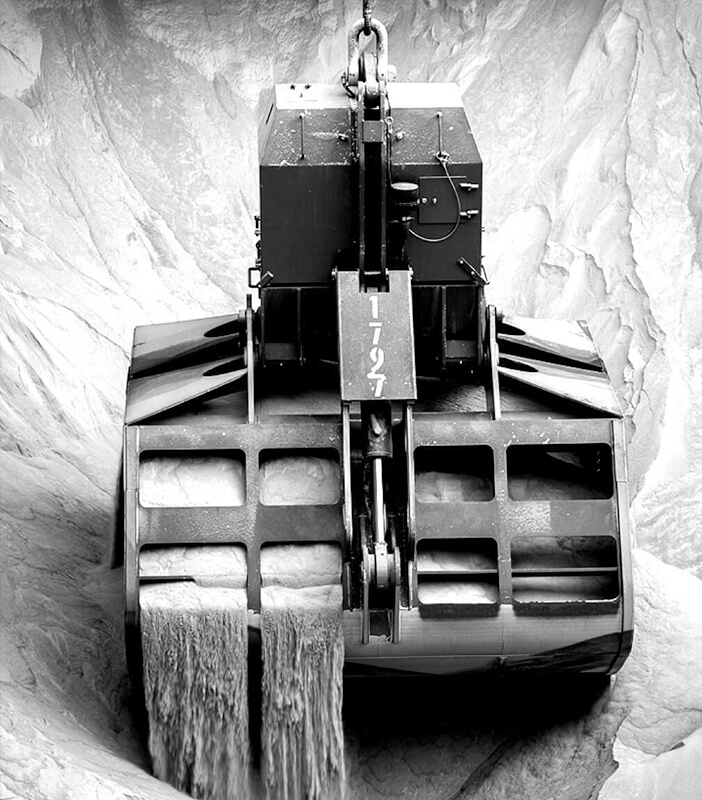

Since the introduction of our diesel Grabs to Geelong, vessel discharge rates using ships gear have never been faster. Stevens’ Grabs have becoming the preferred Grabs of stevedores in Geelong and other Ports nationally due to their ease of use, the quality of the Grabs and the high standards of our service and maintenance team to ensure the smooth running of our equipment. European Grab designs together with Australian designed technology provide a complete smart system that improves servicing, fault finding and Grab repair turnaround.

Our diesel Grabs have proved superior at maintaining higher discharge rates when compared to other Grabs. Our Grab fleet now consists of three different sizes to maximise productivity per vessel, regardless of product.